What Is PP Honeycomb Core

PP honeycomb core is a type of lightweight and durable core material made from Polypropylene (PP) plastic. The PP Honeycomb Core has a unique honeycomb structure that provides high strength and stiffness with minimal weight. This makes it an ideal material for various applications in industries such as aerospace, automotive, marine, construction, and packaging. It is resistant to water, chemicals, and impacts, making it an excellent material for products that require high durability and strength. PP Honeycomb core can be easily formed, cut, and shaped to fit a wide range of product designs and applications.

Advantages of PP Honeycomb Core

High strength-to-weight ratio

Although PP Honeycomb Core is lightweight, it is still incredibly strong. Its unique honeycomb structure provides excellent strength-to-weight ratio, making it ideal for applications where strength is important but weight is a concern.

Corrosion resistance

PP Honeycomb Core is highly resistant to the effects of corrosion, making it ideal for use in humid or wet environments. It is also resistant to chemicals, making it suitable for use in harsh chemical environments.

Temperature resistance

PP Honeycomb Core can withstand a wide range of temperatures, from below freezing to over 100 degrees Celsius. This makes it ideal for use in both indoor and outdoor environments.

Sound and thermal insulation

The honeycomb structure of PP Honeycomb Core also provides excellent sound and thermal insulation, making it ideal for use in construction applications such as walls, ceilings, and floors.

Why Choose Us

Our Team

Haozhuo is a High-tech enterprise specializing in R&D, production, and sales of thermoplastic honeycomb composite materials and other composite materials.

Production Equipment

It is equipped with various cutting and engraving equipment and a large continuous laminating machine to form a production chain from core materials to panel products.

Global Shipping

And our products export to the United States, Germany, Italy and other European and American countries as well as other emerging industrial countries like Brazil, Russia.

Our Product

Polypropylene(PP) honeycomb core, thermoplastic honeycomb panel, sandwich panel , Other functional composite panel, etc.

Types of PP Honeycomb Core

Honeycomb composite panel

Honeycomb composite panels are a type of sandwich structure panel made by bonding two flat skins, typically made of aluminum, fiberglass, or carbon fiber, to a central core material made of paper honeycomb, aluminum honeycomb, or other lightweight materials. The result is a lightweight yet strong and rigid panel with high strength-to-weight ratio, excellent thermal insulation, and sound insulation properties. Honeycomb composite panels are used in a wide range of applications, such as aerospace, automotive, construction, and marine industries, among others.

Plastic honeycomb composite panels

Plastic honeycomb composite panels are made up of a lightweight and strong honeycomb core sandwiched between two plastic panels. These panels are durable, lightweight, and offer excellent structural stability. They are commonly used in a variety of industrial and commercial applications, including aerospace, automotive, construction, and marine industries. Plastic honeycomb composite panels offer superior strength-to-weight ratios, making them ideal for applications requiring high strength and stiffness. They also offer excellent thermal and acoustic insulation properties, making them suitable for use in applications that require soundproofing or temperature control.

Fiberglass sandwich panel

Fiberglass sandwich panel is a structural panel that consists of two flat rigid sheets of fiberglass reinforced plastic (FRP) and a core material such as foam, balsa wood, or honeycomb. The core material provides strength and stiffness to the panel while the FRP skin provides protection from weather, corrosion, and impact. The sandwich panel is lightweight, durable, and has excellent insulation properties making it ideal for use in construction, transportation, aerospace, and marine industries.

Frp honeycomb panel

FRP Honeycomb Panel refers to a type of composite panel made by sandwiching a honeycomb core between two layers of Fiberglass Reinforced Polymer (FRP). The honeycomb core is typically made of polycarbonate, aluminum, or expanded polystyrene and helps to reduce the weight of the panel while maintaining structural strength. The FRP skin provides corrosion resistance, durability, and aesthetics, making FRP honeycomb panels suitable for various applications such as building cladding, transportation, and marine. These panels offer high strength-to-weight ratio, excellent fire resistance, and ease of installation.

PP Honeycomb Core, also known as Polypropylene Honeycomb Core, is a lightweight and durable material composed of hexagonal-shaped cells made from polypropylene plastic. It has a strong, yet lightweight structure which makes it an ideal material for use in various applications such as packaging, transportation, and construction.The PP Honeycomb Core is made by extruding polypropylene resin into a honeycomb structure. This structure is then laminated with a variety of materials such as paper, aluminum, or fiber to give it additional properties such as strength, rigidity, corrosion resistance, or insulation. One of the key advantages of PP Honeycomb Core is its low weight-to-strength ratio. This feature makes it an excellent choice for lightweight and portable applications such as packaging crates and boxes, sandwich panels, and reinforcement materials for composite structures.

Application of PP Honeycomb Core

Packaging: PP honeycomb core is widely used in packaging due to its excellent cushioning and shock-absorbing properties. It is commonly used to package fragile and delicate products like electronic devices, glassware, and sensitive equipment.

Automotive industry: PP honeycomb is used extensively in the automotive industry for various applications such as instrument panel carriers, bumper cores, roof covers, and headliners. It is an excellent replacement for traditional materials like metal and plastic due to its low weight and high strength.

Aerospace industry: PP honeycomb core is suitable for use in the aerospace industry as it can withstand extreme temperatures and high pressure. It is commonly used in composite sandwich panels for aircraft floors, interior cabins, and structural components.

Construction industry: PP honeycomb core is also used in the construction industry to provide insulation, soundproofing, and lightweight panels for various applications like facades, ceilings, and walls in buildings.

Furniture industry: PP honeycomb core is also employed in the manufacture of a wide range of home and office furniture, including desks, shelves, and cabinets. It is valued for its lightweight and high strength properties.

Extrusion: The first step involves the extrusion of PP sheets into a flat honeycomb shape. The polypropylene material is melted, and then extruded through a die to form a honeycomb structure.

Stretching: After extrusion, the honeycomb sheet is stretched in both directions, creating small cells that are uniform in size and shape. This stretching process increases the strength and stability of the honeycomb core.

Cutting: Once the honeycomb sheet has been stretched, it is cut to the desired size and shape. This can be done using a saw or other cutting tool, depending on the specific requirements of the product being manufactured.

Bonding: The final step involves bonding the honeycomb core to a variety of different materials, such as aluminum, fiberglass, or paper. This is typically done using a high-strength adhesive that can withstand the pressures and stresses of the application.

Size and shape

PP honeycomb cores come in various shapes and sizes, so you need to consider the dimensions of your desired product and choose a honeycomb core that fits those dimensions.

Material properties

PP honeycomb cores can differ in terms of their material properties, such as their strength, weight, stiffness, and resistance to moisture and chemicals. You need to select a honeycomb core that has the appropriate properties for your intended use.

Cell size and thickness

The cell size and thickness of a honeycomb core can affect its performance, such as its strength and stiffness. You should choose a honeycomb core with a cell size and thickness that match your desired performance characteristics.

Environmental considerations

If your application requires a honeycomb core that can withstand certain environmental conditions, such as extreme temperatures or exposure to UV radiation or chemicals, you need to choose a honeycomb core that has been tested and certified for those conditions.

Price

Finally, you need to consider the cost of the honeycomb core and your budget. There may be trade-offs between price and performance, so you need to determine which features are most important for your particular application and select the honeycomb core that offers the best combination of performance and cost.

Working Principle of PP Honeycomb Core

The working principle of a PP honeycomb core involves the use of a lightweight and strong material to provide structural support for various applications. The core is made up of a series of hexagonal cells that are crafted from polypropylene (PP) plastic. The cells have a honeycomb-like structure that provides excellent strength and durability while remaining lightweight.When pressure is applied to the honeycomb core, the cells compress and distribute the force evenly across the surface area of the material. This makes it an ideal choice for applications where weight is a concern, such as in aerospace, automotive, and marine industries.The unique properties of PP honeycomb core make it a popular choice for insulation, soundproofing, and packaging materials. The core can also be sandwiched between two thin sheets of material, such as aluminum, to create a composite panel that offers superior rigidity and strength.

How Environmentally Friendly Is PP Honeycomb Core

Polypropylene (PP) honeycomb core is a highly environmentally friendly material. It is made from 100% recyclable polypropylene, which is a thermoplastic material that can be fully recycled without losing its quality or properties.PP honeycomb core has a low carbon footprint because it requires less energy and resources to produce compared to other materials such as aluminum honeycomb. It is lightweight, which means that it has a smaller environmental impact during transportation and installation.The production process of PP honeycomb core also generates fewer greenhouse gas emissions compared to other materials, making it a more sustainable option for various industrial applications.PP honeycomb core can be reused or repurposed for other applications, which adds to its sustainability. It is also resistant to chemicals and UV radiation, which makes it an excellent choice for outdoor applications, as it can withstand harsh weather conditions.PP honeycomb core is an eco-friendly and sustainable material that offers many benefits in terms of reducing environmental impact while providing strength and durability for various applications.

How Does PP Honeycomb Core Compare to Other Types of Honeycomb Cores

PP honeycomb core made from polypropylene material, is a lightweight and cost-effective option compared to other types of honeycomb coresCompared to aluminum honeycomb cores, PP honeycomb cores have a lower density which makes them easier to handle and transport. They also have higher impact resistance and are less prone to denting or cracking. Additionally, PP honeycomb cores are not as susceptible to oxidation and corrosion as aluminum cores.Compared to Nomex or Kevlar honeycomb cores, PP honeycomb cores have a higher resistance to moisture, chemicals, and UV radiation which makes them ideal for outdoor and marine applications. They also have a higher energy absorption capacity which makes them suitable for high-impact applications such as vehicle crash absorption.PP honeycomb cores offer a great combination of properties such as lightweight, durability, impact resistance, and cost-effectiveness, making them a popular choice for various applications ranging from aerospace and automotive to marine and construction industries.

How Strong Is a PP Honeycomb Core

PP honeycomb core is a lightweight and durable material that is commonly used in various applications such as aerospace, construction, transportation, and packaging industries. The strength of a PP honeycomb core depends on a few factors such as the cell size, thickness, and the density of the core.The cell size and thickness of the honeycomb core determine its rigidity and stiffness. A smaller cell size and thicker core result in a more rigid and stronger material. On the other hand, a larger cell size and thinner core provide a flexible and lightweight material, but with reduced strength.

The density of the honeycomb core also plays a significant role in its strength. A higher density core provides a higher strength-to-weight ratio. However, increasing the density also increases the weight of the material, which may not be desirable for certain applications.PP honeycomb core is a strong and durable material that can withstand a variety of forces. Its strength depends on various factors, but it is generally known for its high strength-to-weight ratio, making it an ideal material for lightweight and high-performance applications.

How to Maintain PP Honeycomb Core

Regular inspection

Inspect the honeycomb core periodically to ensure any damage or wear. Make sure there are no cracks or dents on the core.

Cleaning

Clean the honeycomb core with mild soap and water using a soft-bristled brush or sponge. Do not use harsh chemicals or abrasive materials as it might damage the structure.

Avoid impact

Avoid heavy impact or pressure on the core as it may lead to cracking or deformation.

Store properly

Store the honeycomb core in a dry and cool place, away from direct sunlight and moisture.

Protecting from sunlight and heat

Avoid exposing the honeycomb core to direct sunlight and high temperatures as it can cause warping and distortion.

Handle with care

Handle the honeycomb core carefully during transportation, installation, and maintenance to prevent it from damage or deformation.

Our Factory

Our company covers an area of 30,000 square meters. It is equipped with various cutting and engraving equipment and a large continuous laminating machine to form a production chain from core materials to panel products. At present, it has an annual production capacity of 1.5 million square of thermoplastic sheet.

Video

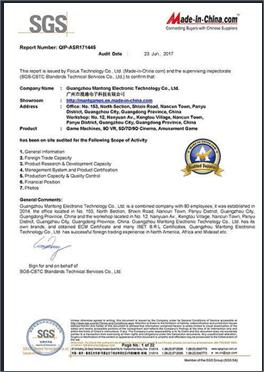

Certifications

FAQ

Q: What is honeycomb core material?

Q: How is a PP honeycomb core produced?

Q: What are the benefits of using a PP honeycomb core?

Q: How does a PP honeycomb core compare to other types of honeycomb cores?

Q: What industries use PP honeycomb cores?

Q: What are the different types of PP honeycomb cores available?

Q: How strong is a PP honeycomb core?

Q: What temperature range can a PP honeycomb core withstand?

Q: How do you cut a PP honeycomb core to size?

Q: Can a PP honeycomb core be recycled?

Q: Is a PP honeycomb core fire-resistant?

Q: How does a PP honeycomb core respond to moisture?

Q: How long does a PP honeycomb core typically last?

Q: What is the maximum thickness of a PP honeycomb core?

Q: What is the thermal conductivity of PP honeycomb cores?

Q: Are PP honeycomb cores resistant to chemicals and corrosion?

Q: Can PP honeycomb cores be used for sound insulation?

Q: What industries commonly use PP honeycomb cores in their manufacturing processes?

Q: What is the density of PP honeycomb cores?

Q: Can PP honeycomb cores be used in marine applications?

As one of the most professional pp honeycomb core manufacturers and suppliers in China, we're featured by quality products and good service. Please rest assured to buy customized pp honeycomb core at competitive price from our factory.

Honeycomb Building Panels, Wood Grain Honeycomb Panel, Honeycomb Fiberglass Board